Prevost Aluminum Tapping Flange For Pipe

Price range: $17.56 through $64.87

- Description

- Additional information

Description

Prevost Aluminum Tapping Flange For Pipe

Technical specifications

- Technology :PPS Grip Concept

- Operating pressure :29 to 232 psi

- Vacuum capability :0.59 inHg (vacuum 98%)

- Temperature : 5 deg. F to158 deg. F

- Construction :Pipe and fittings: alu.

- Highlight :Scalable system

- Meets standards :ASME B31.3 REACH

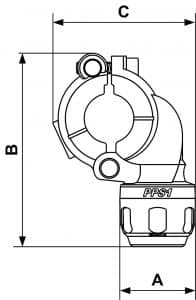

| Reference | For pipe OD (in) | A inch | B inch | C inch |

|---|---|---|---|---|

| PPS1 BP2516 | 1/2″ | 1.260 | 3.701 | 2.756 |

| PPS1 BP2520 | 3/4″ | 1.496 | 3.858 | 2.835 |

| PPS1 BP3216 | 1/2″ | 1.260 | 3.701 | 2.756 |

| PPS1 BP3220 | 3/4″ | 1.496 | 3.858 | 2.835 |

| PPS1 BP4016 | 1/2″ | 1.260 | 4.803 | 4.016 |

| PPS1 BP4020 | 3/4″ | 1.496 | 5.000 | 4.016 |

| PPS1 BP4025 | 1″ | 1.811 | 5.118 | 4.055 |

| PPS1 BP5016 | 1/2″ | 1.260 | 4.803 | 4.016 |

| PPS1 BP5020 | 3/4″ | 1.496 | 5.000 | 4.016 |

| PPS1 BP5025 | 1″ | 1.811 | 5.118 | 4.055 |

| PPS1 BP6320 | 3/4″ | 1.496 | 6.417 | 5.787 |

| PPS1 BP6325 | 1″ | 1.811 | 6.575 | 5.787 |

| PPS1 BP6332 | 1 1/4″ | 2.244 | 6.496 | 5.787 |

| PPS1 BP8020 | 3/4″ | 1.496 | 6.417 | 5.787 |

| PPS1 BP8025 | 1″ | 1.811 | 6.575 | 5.787 |

| PPS1 BP8032 | 1 1/4″ | 2.244 | 6.496 | 5.787 |

| PPS1 BP10025 | 1″ | 7.874 | 6.260 | |

| PPS1 BP10032 | 1 1/4″ | 8.465 | 6.260 |

Prevost PPS Aluminum Tapping Flange

The Prevost PPS Aluminum Tapping Flange is an innovative retrofit solution designed to add new drop lines to an existing compressed air network without the need to cut, dismantle, or remove sections of the main pipe. This “saddle-style” clamp fits securely around the pipe exterior, allowing for the rapid creation of a new outlet point in minutes.

Engineered for performance, this flange features a built-in condensate avoidance design. By drawing air from the center of the air stream rather than the bottom of the pipe, it acts as an internal “swan neck,” preventing moisture and contaminants flowing along the bottom of the main header from entering your tools.

Key Features & Benefits

- No Pipe Cutting Required: Eliminates the difficult and risky process of cutting a pressurized or existing main header. Simply drill a hole using the specific jig and clamp the flange in place.

- Dry Air Delivery: The internal probe design ensures that air is drawn from the clean, dry center of the airflow, preventing the condensate that naturally runs along the bottom of the pipe from entering the drop line.

- Rapid Retrofit: The fastest way to expand a system. A new workstation or machine drop can be installed in under 5 minutes with minimal system downtime.

- Leak-Proof Seal: Features a high-quality, pre-lubricated O-ring that creates a perfect seal around the drilled hole, while the aluminum saddle provides rigid structural support.

- Self-Aligning: Designed to automatically align with the drilled hole for a secure fit, preventing flow restriction.

Technical Specifications

- Part Series: PPS1 BP (Quick Assembly Flange)

- Body Material: Aluminum Alloy

- Fasteners: Stainless Steel Bolts

- Outlet Type: Female Thread (BSPP/NPT) – Allows for connection to a male stud or valve.

- Operating Pressure: Up to 232 PSI (16 bar)

- Operating Temperature: -4°F to +176°F (-20°C to +80°C)

- Compatibility: Available for all main PPS diameters (e.g., 25mm to 100mm main line sizes).

Ideal Applications

- Adding New Workstations: Quickly bringing a new air drop to a newly installed bench or machine in a busy factory.

- System Expansion: Tapping into a high-level header to feed a new extension or room.

- Drain Installation: When installed inversely (at the bottom of the pipe), it can be used to create a drainage point for condensate removal.