Proper Pipe Selection

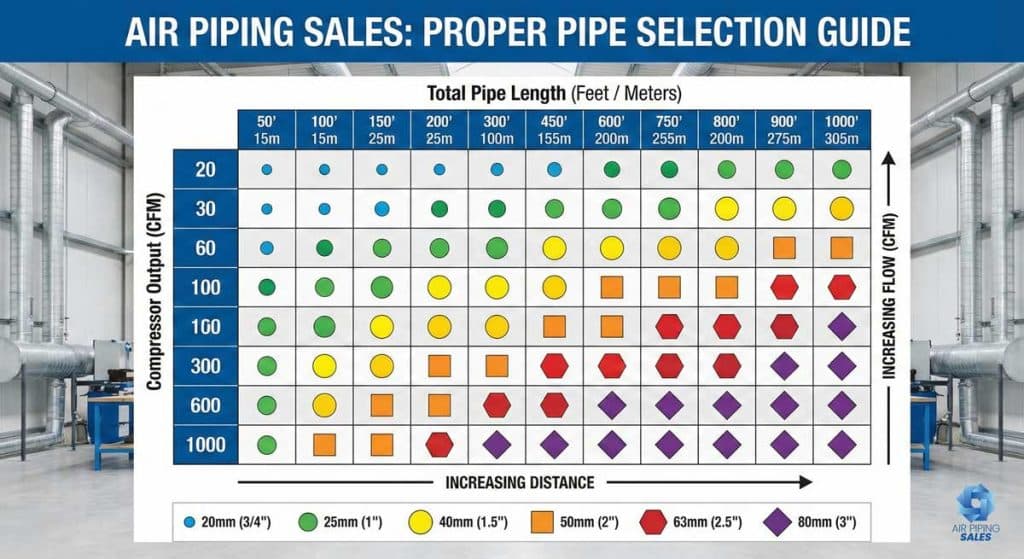

Prevost Sales2026-01-18T16:39:02-07:00Proper Pipe Selection Chart – Find the right diameter based on length and flow.

| Air Compressor Power | Air Compressor Flow rate | Length of the main line | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | HP | Nm3/h | Nl/min | Scfm | 164 ft | 328 ft | 492 ft | 984 ft | 1640 ft | 2460 ft | 3280 ft | 4265 ft | 5249 ft |

| 2.2 | 3 | 22 | 367 | 13 | 1/2’’ | 1/2’’ | 1/2’’ | 1/2’’ | 3/4’’ | 3/4’’ | 3/4’’ | 3/4’’ | 1’’ |

| 3 | 4 | 30 | 500 | 18 | 1/2’’ | 1/2’’ | 1/2’’ | 3/4’’ | 3/4’’ | 3/4’’ | 1’’ | 1’’ | 1’’ |

| 4 | 5.5 | 40 | 667 | 24 | 1/2’’ | 1/2’’ | 3/4’’ | 3/4’’ | 1’’ | 1’’ | 1’’ | 1’’ | 1/4’’ |

| 5.5 | 7.5 | 50 | 834 | 29 | 1/2’’ | 3/4’’ | 3/4’’ | 3/4’’ | 1’’ | 1’’ | 1’’ | 1/4’’ | 1/4’’ |

| 7.5 | 10 | 70 | 1167 | 41 | 3/4’’ | 3/4’’ | 3/4’’ | 1’’ | 1’’ | 1/4’’ | 1/4’’ | 1/4’’ | 1/4’’ |

| 11 | 15 | 100 | 1667 | 59 | 3/4’’ | 1’’ | 1’’ | 1’’ | 1/4’’ | 1/4’’ | 1/4’’ | 1 1/2’’ | 1 1/2’’ |

| 15 | 20 | 150 | 2500 | 88 | 1’’ | 1’’ | 1/4’’ | 1/4’’ | 1/4’’ | 1 1/2’’ | 1 1/2’’ | 1 1/2’ | 1 1/2’ |

| 18 | 25 | 180 | 3000 | 106 | 1’’ | 1’’ | 1/4’’ | 1/4’’ | 1 1/2’’ | 1 1/2’ | 1 1/2’ | 2’’ | 2’’ |

| 22 | 30 | 220 | 3667 | 129 | 1’’ | 1/4’’ | 1/4’’ | 1 1/2’’ | 1 1/2’ | 1 1/2’ | 2’’ | 2’’ | 2’’ |

| 26 | 35 | 260 | 4334 | 153 | 1/4’’ | 1/4’’ | 1/4’’ | 1 1/2’ | 1 1/2’ | 2’’ | 2’’ | 2’’ | 2’’ |

| 30 | 40 | 300 | 5000 | 176 | 1/4’’ | 1/4’’ | 1 1/2’’ | 1 1/2’’ | 2’’ | 2’’ | 2’’ | 2’’ | 2 1/2’’ |

| 37 | 50 | 370 | 6167 | 218 | 1/4’’ | 1/4’’ | 1 1/2’ | 1 1/2’ | 2’’ | 2’’ | 2’’ | 2 1/2’’ | 2 1/2’’ |

| 45 | 60 | 450 | 7500 | 265 | 1 1/2’’ | 1 1/2’’ | 1 1/2’ | 2’’ | 2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ |

| 55 | 75 | 550 | 9167 | 324 | 1 1/2’ | 1 1/2’ | 2’’ | 2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 3’’ |

| 75 | 100 | 750 | 12500 | 441 | 2’’ | 2’’ | 2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 3’’ | 3’’ | 3’’ |

| 90 | 120 | 900 | 15000 | 529 | 2’’ | 2’’ | 2’’ | 2 1/2’’ | 2 1/2’’ | 3’’ | 3’’ | 3’’ | 3’’ |

| 110 | 150 | 1100 | 18334 | 647 | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 3’’ | 3’’ | 3’’ | 3’’ | 4’’ |

| 130 | 175 | 1300 | 21667 | 765 | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 3’’ | 3’’ | 3’’ | 4’’ | 4’’ |

| 160 | 215 | 1600 | 26667 | 941 | 2 1/2’’ | 2 1/2’’ | 2 1/2’’ | 3’’ | 3’’ | 3’’ | 4’’ | 4’’ | 4’’ |

| 200 | 270 | 2000 | 33334 | 1176 | 3’’ | 3’’ | 3’’ | 3’’ | 3’’ | 4’’ | 4’’ | 4’’ | 4’’ |

| 250 | 340 | 2500 | 41667 | 1471 | 3’’ | 3’’ | 3’’ | 3’’ | 4’’ | 4’’ | 4’’ | 6’’ | 6’’ |

| 300 | 405 | 3000 | 50000 | 1765 | 4’’ | 4’’ | 4’’ | 4’’ | 4’’ | 4’’ | 6’’ | 6’’ | 6’’ |

| 350 | 475 | 3500 | 58334 | 2059 | 4’’ | 4’’ | 4’’ | 4’’ | 4’’ | 6’’ | 6’’ | 6’’ | 6’’ |

| 400 | 540 | 4000 | 66667 | 2353 | 4’’ | 4’’ | 4’’ | 4’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ |

| 450 | 600 | 4500 | 75000 | 2647 | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ |

| 500 | 700 | 5000 | 83334 | 2941 | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ |

| 600 | 810 | 6000 | 100000 | 3529 | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ |

| 700 | 950 | 7000 | 116667 | 4118 | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | |

| 800 | 1080 | 8000 | 133334 | 4706 | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | 6’’ | |||

The Science of Sizing: Why Diameter Matters

Selecting the correct pipe diameter is arguably the most critical step in designing your compressed air system. While the air compressor is the heart of your operation, the piping is the arteries. If the arteries are too narrow, the heart has to work harder, energy is wasted, and the “muscles” (your pneumatic tools) won’t have the strength to function properly.

Many shop owners make the mistake of sizing their piping based on the size of the compressor’s outlet port. For example, if a compressor has a ¾” outlet, they assume a ¾” pipe is sufficient for the whole facility. This is a myth. The outlet port is designed only for the short distance of air leaving the machine. Once that air must travel 50, 100, or 200 feet to a workstation, friction builds up against the pipe walls. Without a wide enough diameter to accommodate the volume of air, you experience significant “pressure drop.”

This page features our Air Pipe Sizing Chart, a tool designed to help you balance your flow requirements (CFM) against the distance of your run, ensuring your tools get the pressure they need.

Understanding the Variables: CFM, PSI, and Distance

To use the chart effectively, you need to understand the three main variables that dictate your system’s performance.

- CFM (Cubic Feet per Minute): This is the volume of air moving through the pipe. Think of this as the amount of water flowing through a river. A higher CFM requires a wider riverbed (pipe) to move smoothly. If you try to force high CFM through a narrow pipe, the air becomes turbulent, friction increases, and pressure is lost. You need to know the total CFM rating of your compressor and the consumption rate of your highest-demand tools.

- Distance (Length of Run): This is the physical length of the pipe from the compressor room to the furthest point of use. The longer the air has to travel, the more friction it encounters. A 1-inch pipe might carry 50 CFM perfectly for 20 feet, but at 200 feet, that same pipe will cause a massive pressure drop. Pro Tip: When calculating distance, it is wise to add a safety margin to account for vertical drops and the resistance added by elbows and tees.

- Pressure Drop: This is the enemy of efficiency. Pressure drop is the difference in PSI between the compressor tank and the tool at the end of the line. If your compressor is set to 125 PSI but your impact wrench only reads 90 PSI while running, you have lost 35 PSI to friction inside the pipe. Proper sizing aims to keep this drop below 3-5 PSI.

How to Use the Proper Pipe Selection Chart

Our sizing chart simplifies the fluid dynamics equations into an easy grid.

- Identify your System Pressure: Most charts are calibrated for standard industrial pressures (e.g., 100-125 PSI).

- Locate your CFM: Find the row that matches your compressor’s output. If you are between numbers, always round up.

- Find your Distance: Move across the chart to the column that matches your total pipe length.

- Determine Diameter: The intersection of your CFM and Distance will show the recommended pipe diameter in millimeters (or inches).

Note: Our aluminum pipe systems use metric sizing (mm). A rough conversion is often provided (e.g., 25mm ≈ 1″, 50mm ≈ 2″, 80mm ≈ 3″).

The “Loop” Advantage: How to Cheat the Chart

You may notice that the chart assumes a “straight line” or “dead-end” header. However, if you install your piping in a closed loop (a ring that goes around the shop and connects back to itself), you effectively double the capacity of the pipe.

In a loop system, air can travel in two directions to reach any drop point. This halves the distance the air travels and divides the CFM load. This means a 50mm (2″) pipe in a loop configuration can often handle the workload of a larger straight pipe, saving you money on materials while providing more consistent pressure throughout the facility.

Future-Proofing Your Facility

When selecting your pipe size, remember that it is much cheaper to install a larger pipe today than to rip out and replace a small pipe tomorrow.

If your current compressor puts out 50 CFM, but you plan to add a second compressor or expand your shop floor in the next five years, size your pipe for that future demand. Moving from 25mm to 40mm pipe during the initial installation is a small material cost increase, but it provides a massive increase in flow capacity (roughly 3x the flow) because flow capacity increases exponentially with diameter, not linearly.

Why Aluminum Helps

Finally, the material you choose affects the sizing. Old galvanized iron pipes have rough interiors that create friction and rust over time, narrowing the internal diameter. The aluminum air piping we sell features a calibrated, smooth aluminum bore. This “laminar” surface allows air to slip through with minimal resistance, meaning an aluminum pipe will often outperform a steel pipe of the same nominal size.

Use the chart below to find your perfect fit, and if you are on the borderline between two sizes, we always recommend going with the larger diameter to maximize energy savings and tool performance.